Credit: Jonathan Gitlin

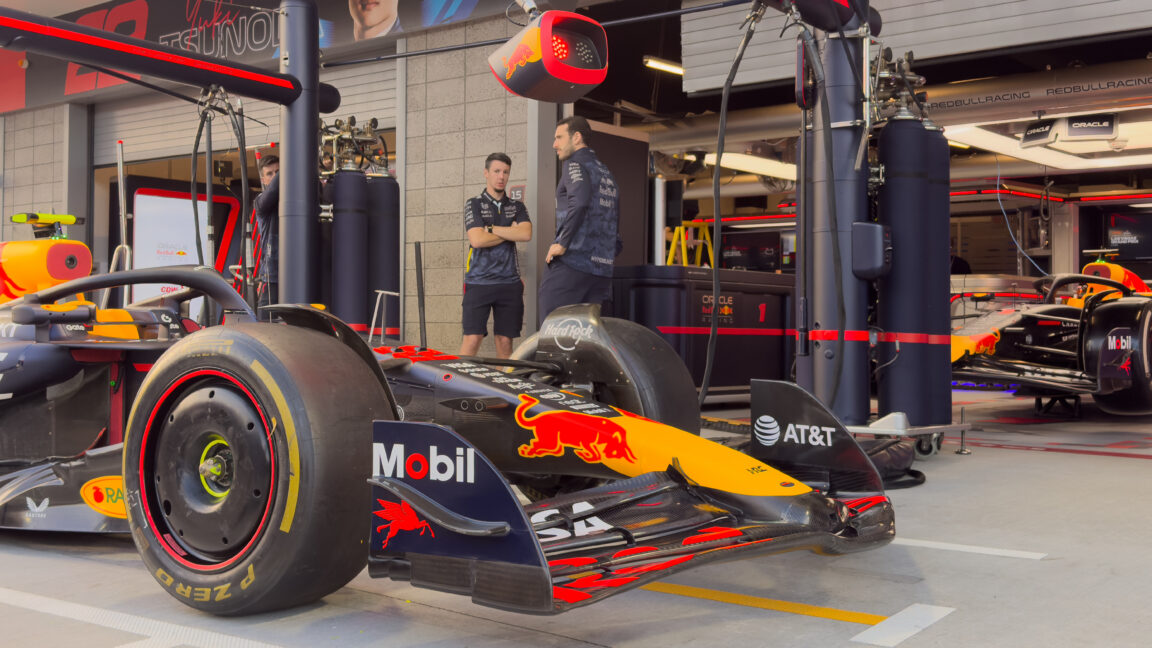

LAS VEGAS—A Formula 1 car runs on soon-to-be-synthetic gasoline, but an F1 team runs on data. It’s always been an engineering-driven sport, and while you can make decisions based on a hunch, the kinds of people who become good engineers prefer something a little more convincing. And the volumes of data just continue to get bigger and bigger each season. A few years ago we spoke to Red Bull Racing about how it stayed on top of the task, but a lot has changed in F1 since 2017, as we found out at this year’s Las Vegas Grand Prix.

It’s hugely popular now, for one thing, even in the United States: a 200 mph soap opera now with 24 episodes a season. Superficially the cars look the same—exposed wheels, front and rear wings, the driver in between some side pods. And the hybrid powertrains that make the cars move are still the same format: 1.6 L turbocharged V6 engines that recover energy from the rear wheels under braking as well as the turbine as it gets spun by hot exhaust gases.

But the cars are actually fundamentally different, particularly the way they generate their aerodynamic grip mostly via ground effect generated by the specially sculpted underside of their floors rather than the front and rear wings. A bigger change lurks in everyone’s accounts. The days where teams were free to spend as much money as they could find are gone.

“We have $140 million to develop the full car and that’s between all the partners; all the products we use with AT&T are part of this cost cap. So that’s why we have to make sure we don’t use too much,” explained Morgan Maia, senior partnerships manager with Oracle Red Bull Racing. The telecoms company has worked with Red Bull for more than a decade but has expanded that role in recent years, linking the garage with a command center at its factory in the UK that lets it bring many more minds to bear on any particular problem than those of the 60 people each team is allowed to bring to each race.

“We learned how to be more efficient because before… we were so focused on performance that we almost forgot about efficiency, about it was full performance, and we have more people now than we had in 2017, for example, in the team, but we are spending less money,” Maia told me.

Bigger data

The number of sensors on each race car has tripled, with around 750 of them, each sending back a different data stream, amounting to around 1.5 terabytes per car per race. Telemetry used to be pretty basic—a TV feed, throttle, brake, and steering applications, and so on. Now a small squad of engineers sits at banks of screens in the back of the garage, hidden away from the cameras, in constant link with their colleagues in the Milton Keynes factory.

“We need as well to bring it straight away to Milton Keynes because it’s helping us to fine-tune the setup—so when you are here on Friday—and it’s helping us as well on Sunday to make the best decision for the race strategy. So that’s why it’s very good to have a lot of data, but you need as well to transfer it back and forth,” Maia said.

“It is a sport of milliseconds, as you know,” said Zee Hussain, head of global enterprise solutions at AT&T. “So the speed of data, the reliability of data, the latency, the security is just absolutely critical. If the data is not going, traversing, at the highest possible speed, and it’s not on a secure and reliable path, that is absolutely without question the difference between winning and losing,” Hussain said.

“I think the biggest latency we have is between Australia and the UK and it’s around 0.3 seconds. It’s nothing. I think if you are on WhatsApp, calling someone is maybe more latency… So it’s impressive,” Maia said.

A rare look at the engineer’s bay in the back of the Red Bull garage.

Credit: Mark Thompson/Getty Images

Beyond race operations, so much of a team’s research and development also takes place digitally now. A few years ago, it would have been impossible to get a live data feed from the team’s off-site wind tunnel to the factory. “At the moment we’re using the one in Bedford, so 20 miles away from the factory, and we are transiting a lot of data because again, we need to take photos every millisecond so you really understand the airflow around the car,” Maia said.

The amount of time any team is allowed to spend in a wind tunnel is now tightly restricted, so being able to send reams of high-resolution images and video is invaluable to Red Bull’s speed of development. “It’s more than terabytes, that’s for sure,” Maia told me. “That’s even more impressive because the quality of the photo and the video you now have, it’s way more advantage for us than five or 10 years ago.”

Those demands are surely only going to grow in the coming years. “It just comes back down to “how do you get as much data transported as quickly as possible and how much does it mimic an actual real environment?” asked Hussain. “So for us, that means can we start thinking about a next generation of AR, VR? Can we start thinking about things like edge compute where you have these applications that are extremely latency-sensitive, so no longer can you afford for a data packet to go from a location here to 200 miles. So can you bring the compute resources even closer, and then what does that unleash?”

-

C114 Communication Network

C114 Communication Network -

Communication Home

Communication Home